Golden Casket - Fountain

Needle Case (photographs courtesty of Lynda Herrod)

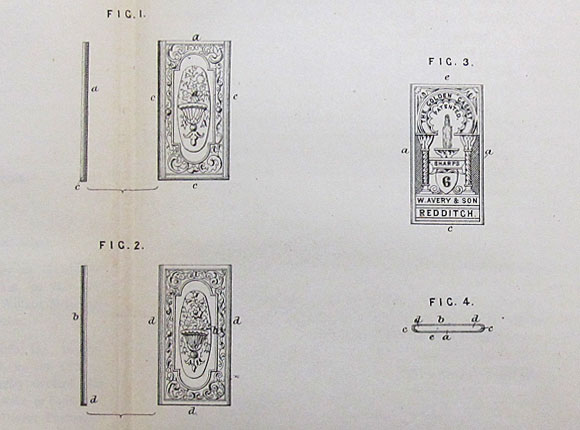

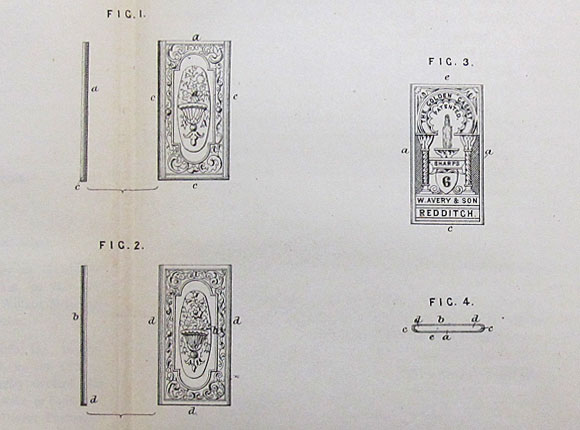

Patent 1868-58

Design Details

Needle Case Type: |

Flat-Names |

Patent/Registered to: |

William Avery of the firm William Avery & Son, Needle Manufacturer from Redditch |

Patent/Design Representation #: |

Mechanical Patent #: 58 |

Patent/Design Registration Date: |

January 7, 1868 |

Location of Patent/Design Registration: |

British Library - Business and Intellectual Property Centre - London

|

Reference #: |

1868-58 |

Dimensions: |

4.8 x 2.3 and 4.1 x 2.1 |

Material: |

Brass |

Name Variations: |

W. Avery & Son - Redditch |

Other Variations: |

a) Golden Casket - Diamond |

Additional Photographs

Back and back detail

Gold

Gold is a bright yellow precious metal used to make jewelry, coins and elaborate decorative objects. Because of its rarity, distinct color,

malleability and non-corrosive properties gold has become the symbol of wealth and historically gold coins were the way in which commerce was often

transacted. Until the 1930s the gold standard was used as the monetary policy between individuals and nations. Jewelry and ornamental

objects made of gold come in several different purities because pure (24k) gold is soft and easily damaged. Most gold is alloyed with other

metals such as copper, silver or palladium, copper being the most common. For example some 18k gold contains 25% copper which gives it a rose

gold color whereas 18k white gold contains 17.3% nickel, 5.5% zinc and 2.2% copper. The detail below is from an Avery style needle case made

of 9k gold. Click on the photo to visit the webpage for this needle case.

Brass

Brass is an alloy of copper and zinc. Many properties make brass appealing, including its brilliant yellow color which resembles gold but

without gold’s costliness; its strength, for brass is stronger and harder than copper; its malleability, which makes it easy to work; and its

resistance to corrosion. The percentage of copper determines the quality of the brass. Blends of 80% copper and 20% zinc create the

finest brass, the kind that wouldn’t crack, the kind most likely used to create brass needle cases. Some needle cases are, however reddish in

color which indicates they had less zinc, perhaps only 15%. Occasionally 12-20% of nickel was added to give the brass a silver appearance -

this was called ‘nickel silver’. Pictured below is a detail of a needle case made of brass. Click on the photo to visit the webpage for

this needle case and see the same item made of nickel-silver.

Gilt

Gilt was used during the Victoria Era to give objects the appearance of gold. Gold plating was not as popular because it was less

durability since the thin layer of gold oxidized and wore off quickly. As a result, manufacturers preferred gilding which involved mixing gold

powder with mercury to form a paste that was applied to the item. Heating then caused the mercury to evaporate leaving the gold powder adhered

to the surface. Thickly applied gilt occasionaly conceals the fine detail of a design, and as an item ages, portions of the gilt deteriorates

and oxidation causes parts of the brass to discolor leaving the item spotty and unattractive. The detailed photo above shows an item with heavy

gilding, whereas the photo below shows the same detail after the heavy gilt was removed. Click on the photo to visit the webpage for this

needle case.